An sani cewa ingancin kayan aikin katako na carbide yana da alaƙa da alaƙa da ingancin samfuran da aka sarrafa.Madaidaicin zaɓin zaɓi na ƙirar carbide yana da mahimmanci don haɓaka ingancin samfuran, rage lokacin sarrafawa, da rage farashin sarrafawa.

Wataƙila kun damu game da yadda za ku zaɓa!Don haka don Allah a karanta wannan labarin cikin haƙuri, ina fata ya kamata ya ƙara taimaka muku.

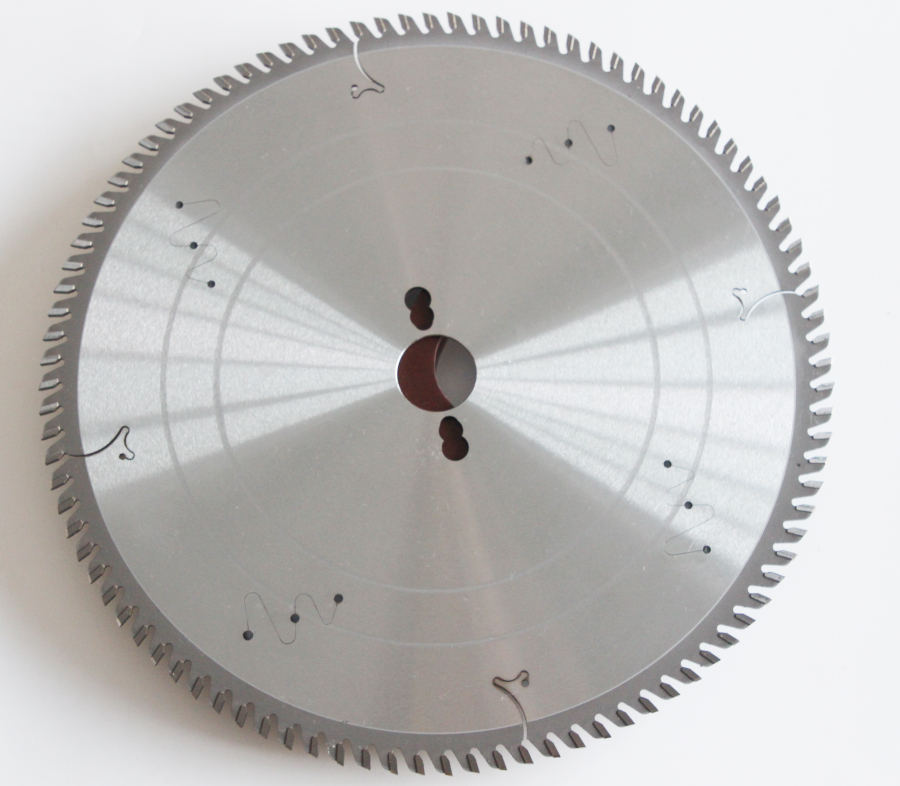

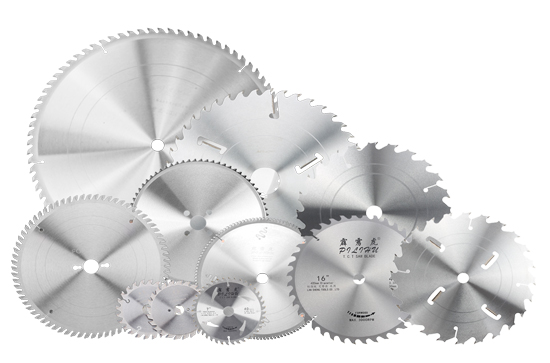

Carbide saw ruwan wukake sun haɗa da sigogi daban-daban kamar nau'in alloy cutter head, kayan kayan aikin, diamita, adadin hakora, kauri, bayanan haƙori, kusurwa, da buɗewa.Waɗannan sigogi suna ƙayyade ƙarfin aiki da yanke aikin tsintsiya.Sabili da haka, lokacin zabar tsintsiya, ya zama dole a zaɓi tsintsiya daidai daidai da nau'in kayan zagayawa, kauri, saurin saƙar, alkiblar saƙo, saurin ciyarwa, da faɗin titin.

Na farko, zabin nau'in carbide ciminti.

Nau'o'in simintin carbide da aka saba amfani dasu sune tungsten-cobalt da tungsten-titanium.Saboda tungsten-cobalt na siminti carbide yana da mafi kyawun juriya mai tasiri, an fi amfani dashi a cikin masana'antar sarrafa itace.Yayin da abun ciki na cobalt ya karu, tasirin tasiri da ƙarfin flesxural na gami zai karu, amma taurin da juriya za su ragu.Zaɓi bisa ga ainihin halin da ake ciki.

Na biyu, zabi na substrate.

1. 65Mn spring karfe yana da kyau elasticity da plasticity, tattalin arziki abu, mai kyau zafi jiyya hardenability, low zafi zazzabi, sauki nakasawa, kuma za a iya amfani da saw ruwan wukake da bukatar low yankan bukatun.

2. Carbon kayan aiki karfe yana da high carbon abun ciki da kuma high thermal watsin, amma ta taurin da kuma ci juriya drop sharply a lokacin da fallasa zuwa zazzabi na 200 ℃-250 ℃, zafi magani nakasawa ne babba, hardenability ne matalauta, da kuma dogon tempering lokaci ne mai sauki. a fasa.Kera kayan tattalin arziki don kayan aiki.

3. Idan aka kwatanta da carbon kayan aiki karfe, gami kayan aiki karfe yana da mafi zafi juriya, sa juriya da kuma mafi kyau handling yi.The zafi nakasawa zafin jiki ne 300 ℃-400 ℃, wanda ya dace da Manufacturing high-sa gami madauwari saw ruwan wukake.

4. Ƙarfe na kayan aiki mai sauri yana da kyau mai kyau, ƙaƙƙarfan ƙaƙƙarfan ƙarfi da rashin ƙarfi, da ƙarancin ƙarancin zafi.Yana da ultra-high-ƙarfi karfe tare da barga thermoplasticity kuma ya dace da masana'anta high-karshen matsananci-bakin ciki saw ruwan wukake.

Na uku, zabin diamita.

A diamita na saw ruwa yana da alaka da sawing kayan aiki da kuma kauri daga cikin sawing workpiece.Diamita na katakon gani yana karami, kuma saurin yankan yana da ƙananan ƙananan;babban diamita saw ruwa yana da mafi girma bukatun a kan saw ruwa da sawing kayan aiki, da sawing yadda ya dace ne kuma high.Ana zaɓin diamita na waje na igiyar gani bisa ga nau'ikan madauwari daban-daban.

Na hudu, zabin adadin hakora.

Gabaɗaya magana, yawan adadin haƙora, ƙarin yankan gefuna za a iya yanke su a cikin lokaci ɗaya, mafi kyawun aikin yankewa, amma ƙarin yankan haƙora yana buƙatar amfani da ƙarin siminti carbide, farashin sawn ya fi girma, amma hakora suna da yawa , Ƙarfin guntu tsakanin hakora ya zama karami, wanda yake da sauƙi don sa igiyar gani don zafi;Bugu da kari, akwai da yawa gani hakora.Lokacin da adadin abincin ba a daidaita ba, adadin yankan kowane haƙori yana da ƙanƙanta, wanda zai kara tsananta jujjuyawar da ke tsakanin yankan da kayan aiki, kuma yana shafar rayuwar sabis na yankan.Yawanci tazarar haƙori shine 15-25mm, kuma ya kamata a zaɓi adadin hakora masu dacewa bisa ga kayan da za a yi.

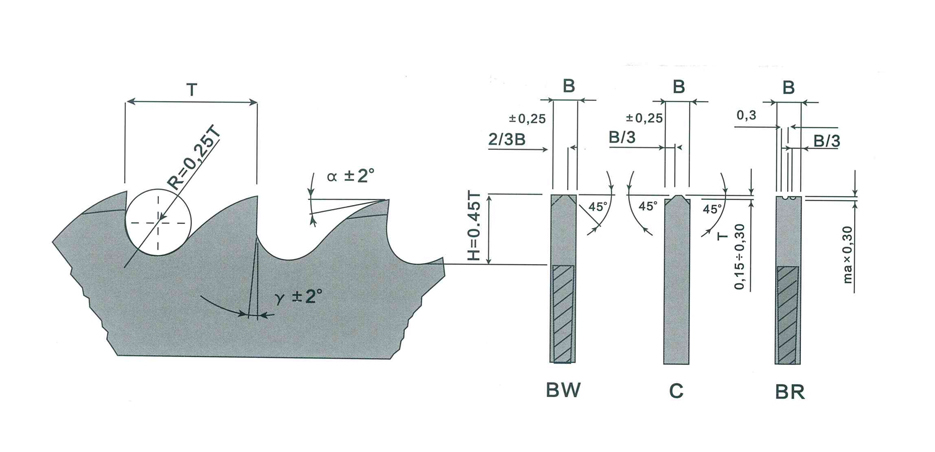

Na biyar, zabin bayanin martabar hakori.

1.The hagu da dama hakora ne mafi yadu amfani, da yankan gudun ne da sauri, da kuma nika ne in mun gwada da sauki.Ya dace da yankan da giciye sawing daban-daban taushi da wuya m itace profiles da yawa allon, Multi-Layer allon, barbashi allon, da dai sauransu Hagu da dama hakora sanye take da anti-repulsion kariya hakora ne dovetail hakora, wanda ya dace da a tsaye a tsaye. yankan kowane nau'in alluna tare da nodes na itace;Hagu da dama hakori saw ruwan wukake tare da korau kwana rake yawanci amfani da manna saboda kaifi hakora da kyau yankan quality, wanda ya dace da bangarori.

2. Lebur ɗin haƙori na lebur yana da ƙarfi, saurin yankewa yana jinkirin, kuma niƙa shine mafi sauƙi.An yafi amfani da sawing na talakawa itace, tare da low cost.Ana amfani da mafi yawa don kayan gani na aluminum tare da ƙananan diamita don rage mannewa yayin yankan, ko don tsagi tsagi don kiyaye ƙasan tsagi.

3. Haƙoran lebur ɗin tsani sun haɗa da haƙoran trapezoidal da haƙoran lebur.Nika ya fi rikitarwa.Zai iya rage fashewar veneer yayin sawing.Ya dace da sawing na daban-daban guda ɗaya da biyu veneer na tushen katako da allunan hana wuta.Domin hana adhesion, aluminum saw ruwan wukake sukan yi amfani da sawn ruwan wukake tare da adadi mai yawa na hakora na tsani lebur hakora.

4. Ana amfani da haƙoran tsani da aka juyar da su sau da yawa a cikin ramin gani mai gani na panel saw.Lokacin da aka ga katako mai fuska biyu, ma'aunin ramin yana daidaita kauri don kammala tsagawar saman ƙasa, sannan babban abin zawar ya kammala aikin sawing na allo.Hana guntun baki a gefen zaga.

Lokacin aikawa: Oktoba-11-2021